Overview

Our integrated solutions drive visibility, collaboration and constructability throughout the entire construction process, bringing every phase into alignment with our clients' end goals. As a WBE certified company, Ruby can help our clients support their growing diversity efforts.

We help our clients to:

- Streamline labor and material costs.

- Reduce schedule constraints.

- Create stability at every stage of construction.

- Minimize risk and increase safety.

- Eliminate unknowns, surprises and delays.

- Gain a comprehensive and proactive understanding of the impact of site logistics.

- Build what others say can't be done.

Construction Engineering

The last thing you want to do is hit an unexpected snag in the field – it costs time and money. Ruby+Associates helps solve problems before they happen. We work out the details before you get to the site, improving efficiency and ultimately improving your bottom line.

For over 35 years, we have provided construction engineering services for virtually every type of building project. Our ability to provide responsive and decisive on-site engineering solutions in a rapidly developing construction environment has earned us a solid reputation and enviable record of success.

- Constructability Review

- Installation Procedures

- On-site Construction Resolution

- Shoring/Underpinning Design

- Temporary Bracing Design

For additional information or project inquiries, please contact Chad Fox, PE, SE at cfox@rubyandassociates.com.

Erection Engineering

Ruby fills the engineering gap between design and construction, facilitating planning that prevents problems during construction, improves safety and reduces costs. How will the structure behave while it is being built? How can our clients minimize the temporary bracing and shoring required, and still provide a safe working environment? How can the structure be used to assist with construction? We design comprehensive plans to stage and erect structural systems in the safest and most efficient manner possible.

- Erection Procedures

- Erection Staging Analysis

- Deconstruction and Demolition Procedures

- Site Specific Erection Plans

- Stability Analysis

- Crane Capacity Reviews

- Critical and Engineered Lift Review

- Apparatus Equipment Procedures and Analysis (Derricks, Hoists, Hydraulic Gantries, etc.)

For additional information or project inquiries, please contact Jeff Gasparott, PE, SECB at jgasparott@rubyandassociates.com.

Building Design

By understanding the impact of design decisions, Ruby serves as a steward for the project’s structural costs. How will design options affect structural needs? How can the structural design minimize steel fabrication and erection costs? How can the design simplify construction? We ask the right questions, helping you find ways to shorten the schedule, reduce construction costs and deliver an outstanding project.

- Structural Expertise for Design/Build

- Conceptual Design

- Building Subsystems

- Foundation Design

- Existing Building Review

For additional information or project inquiries, please contact Thad Greiner, PE, SE at tgreiner@rubyandassociates.com.

Heavy Lift Engineering

Ruby+Associates develops cost-effective, safe and reliable engineered solutions for transporting, handling and installing heavy lifts. We provide a comprehensive approach to heavy lift projects, from selection of rigging components and design of unique lifting devices, to preparation of critical lift procedures, installation procedures and construction sequencing.

- Lift Beam/Spreader Design and Safety Check

- Vessel Tip-up and Laydown Analysis

- Critical and Engineered Lift Review

- Design of Specialty Rigging

- Hydraulic Gantry Lift Engineering

- SCR/Ductwork Demo and Installation Analysis

- Apparatus Equipment Procedures and Analysis (Derricks, Hoists, Hydraulic Gantries, etc.)

For additional information or project inquiries, please contact Chad Fox, PE, SE at cfox@rubyandassociates.com.

Connection Design

Ruby focuses on designing efficient steel connections by applying our knowledge of constructability to deliver a structure that is simpler to detail, fabricate and erect. Initial framing considerations and the subsequent connection design decisions are the keys to providing contractor-friendly projects, without sacrificing the integrity of the structure.

- Structural Steel Connection Design

- Project Standard Shear Connections (Single Angle, Double Angle, Shear Tab, Coped Beams)

- Special Connections (Axially Loaded Beam Connections, Moment Connections, Truss Connections, Vertical Bracing Connections)

- Complex Connections

- Connection Strengthening

- Fabricator and Erector Friendly Design

- Value Engineering Review

For additional information or project inquiries, please contact Ben Miller, PE, SE at bmiller@rubyandassociates.com.

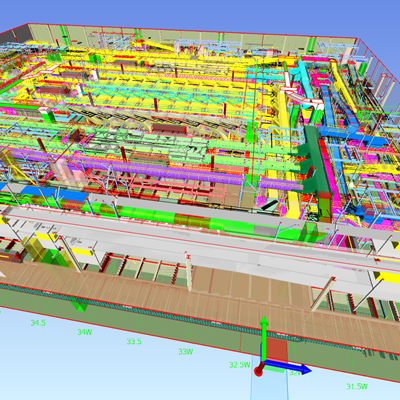

LeanSteel®: Design/Detail

While a typical structural engineer’s final deliverables might result in a set of design drawings, the fabricator can’t get to work without shop details. Ruby’s team can deliver both. LeanSteel® is Ruby’s steel design and detailing process that flattens the steel supply chain.

With LeanSteel®, Ruby’s professionals serve as the Structural Engineer of Record, connection designer, and we produce a LOD 400 structural steel fabrication model and shop fabrication drawings. Ruby’s team begins building the model during schematic design and continues to develop it through the construction document phase.

LeanSteel® eliminates the wasted time and lost knowledge inherent in the traditional steel design and fabrication delivery method by keeping the entire process under the direction of one entity: Ruby. With LeanSteel®, Ruby’s deliverable is not only a set of drawings, but also a fully coordinated and detailed model, with a level of detail exceeding a traditional structural design model.

This LeanSteel® process facilitates advanced coordination and clash detection with other design disciplines – resulting in compressed schedules and increasing your chances for project success.

For additional information or project inquiries, please contact

Todd Lackey at tlackey@rubyandassociates.com

Building Analysis/Reinforcement

Structural engineering doesn’t stop after the ribbon-cutting ceremony. The building needs change, new equipment or conveyors are added, production increases, manufacturing process is changed, occupancy is modified, or new owners bring different business goals to the space. Ruby+Associates performs existing building analysis and structural reinforcement design to ensure your operations can be accommodated as efficiently as possible in the space that you have.

- Truss Evaluation and Reinforcement

- Floor Reinforcing

- Roof and Wall Openings

- Vibration Analysis

- Rooftop Unit Supports

- Column Removal

- Hanging Scoreboards and Event Rigging

For additional information or project inquiries, please contact Thad Greiner, PE, SE at tgreiner@rubyandassociates.com.

Contact.

30300 Telegraph Road, Suite 400Bingham Farms, MI 48025 220 Lyon Street NW, Suite 540

Grand Rapids, MI 49503

1.248.865.8855

1.jpg?w=400&h=400&mode=crop&scale=both)